L&T Group Websites

- Corporate

- Corporate – Arabic

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Development Projects Limited

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- Power

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

Ash Management

In the electricity generation process, ROM coal which contains ~35% of Ash content is fed into the boiler in pulverized form where it immediately ignites to produce the heat. After the ignition process, coarser Ash particles, referred to as bottom Ash, settle in the furnace chamber's bottom, while the lighter Ash - termed Fly Ash, remain suspended in the flue gas and collected in ESP. Bottom Ash is pumped to Pond Ash dyke in the slurry form. Fly Ash possesses siliceous properties, making it a valuable resource for Cement manufacturing, RMC plants and Brick manufacturing. On the other hand, bottom Ash is utilized in landfilling for constructing roads, flyovers, and reclaiming low-lying areas.

Nabha Power Limited (NPL) has established long and medium-term contracts with renowned Cement manufacturers to supply Fly Ash. Additionally, NPL also ensures that Fly Ash requirement of local RMC plants is met. Notably, NPL ensures that 100% of the Bottom Ash from the pond is utilised in road and land filling activities. Through these operations, NPL actively promotes a circular economy and contributes significantly to creating a greener environment. NPL has taken another significant step by installing an Automatic machine for the packing of Fly Ash in bags. This strategic move aims to cater to the needs of small buyers who lack the required infrastructure for Fly Ash storage, while simultaneously contributing to the reduction of transportation costs.

To enhance customer service, NPL has implemented a Bulker Fleet Management system within the plant. This system ensures precise monitoring and control of vehicle movements at different points, thus enabling us to optimise the Turnaround Time of the vehicles.

Through the implementation of state-of-the-art technology systems, NPL has adopted a proactive approach to dispatching Fly Ash, ensuring airtight containment and zero leakage into the environment. This commitment to excellence has resulted in a remarkable 100% utilisation of both Fly Ash and Bottom Ash over the years, earning NPL well-deserved accolades and recognition, including recent awards:

- Efficient Fly Ash Management Award 2024 - NPL adjudged as Winner in the “Efficient Management of Fly Ash - TPPs ≥ 500 MW (North Zone)” category at the Fly Ash Utilisation-2024 Awards organised by Mission Energy Foundation.

- National Environment Excellence Awards 2023 - NPL was adjudged as the Winner in the “Fly Ash Utilisation (Private Sector)” category at the 2nd CEE National Environment Excellence Awards.”

-

High Volume Pond Ash-Clay Bricks

A strong & light weight Product for building construction

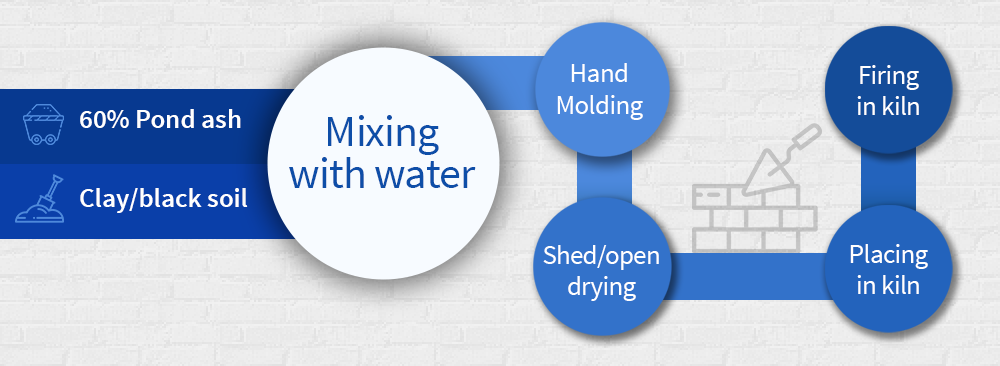

About 60% Pond ash mixed with 40% clay/ black soil can be utilized for manufacturing clay ash bricks with traditional manufacturing process.

Manufacturing Process

Highlights of the process

- Manufacturing process is similar to traditionally followed clay brick

- No change in kiln operation-even single old kiln is

- No additional labour and equipment

Advantages of the process

- Less coal consumption in firing process

- Higher compressive strength & light weight as compared to clay

- Less cost of transportation as more bricks can be transported in one truck load because of light

- Manufacturing process is environment friendly as it helps to reduce soil degradation and pollution because of reduced soil & coal

- Better shaped red bricks

-

Fly Ash/Pond Ash Bricks

A clean & Green Product for construction work

Advantages of Fly Ash/Pond Ash Bricks

- Fly ash/Pond ash bricks are produced with/without

- Plaster thickness required will, be less compared to clay bricks, thus saving of cement mortar.

- These bricks are environment friendly as:

- It uses fly ash/pond ash, which is by - product of thermal power

- Saves agricultural land which is used for manufacturing clay

- Less energy intensive compared to clay bricks and helps in keeping clean environment.

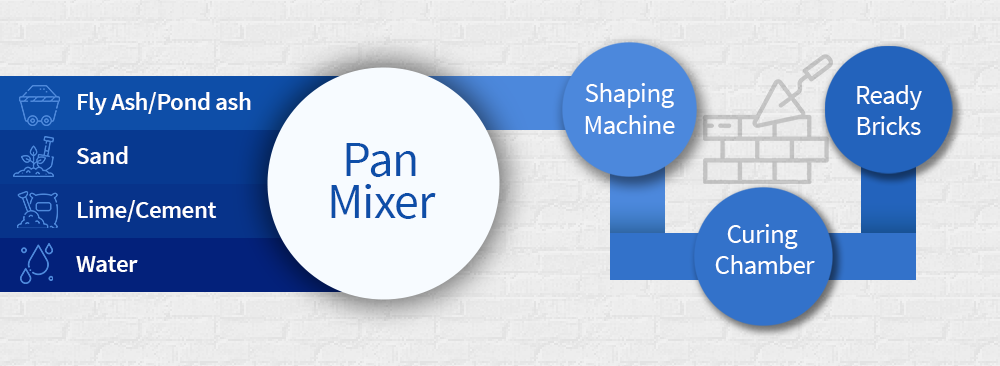

Manufacturing Process

- Fly Ash Bricks are machine made bricks manufactured by hydraulic or vibratory press

- Raw material required are fly ash & pond ash - a by-product of thermal power station, hydrated lime, gypsum, locally available sand/stone dust and

- Ordinary Portland Cement can also be used in place of hydrated lime and

- Raw materials in the required proportion are mixed in the pan mixer to have a semi dry uniform

- Semi dry mix is placed in the moulds of hydraulic/vibro

- Moulded bricks are air dried for one/two days in a shed depending upon the weather conditions and then water cured for 14-21

- The bricks thus produced are sound, compact and uniform in

- Bureau of Indian Standards have issued code IS:12894-2002 for ash